1.000 - 3.000 Dia. High Feed Mills

Shank & Shell Mount

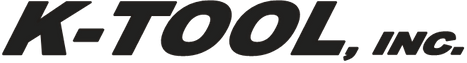

Shank Tools

- - Higher Feed Rates

- - Faster Material Removal

- - Ramping & Plunging Capabilities

- - Free Cutting

| Tool Info. Shank Tools |

||||||||||

| Tool # | Flutes | D | L-1 | L | S | Plunge “P” | Ramp | Insert | Screw | Wrench |

| HF-100 | 2 | 1.000 | 1.500 | 3.750 | 1.000 | .031 | 10° | ARP-33 | 538T | T-10 |

| HF-125 | 3 | 1.250 | 1.500 | 3.750 | 1.000 | .031 | 5° | |||

| HF-150 | 4 | 1.500 | 1.500 | 3.750 | 1.000 | .031 | 3° | |||

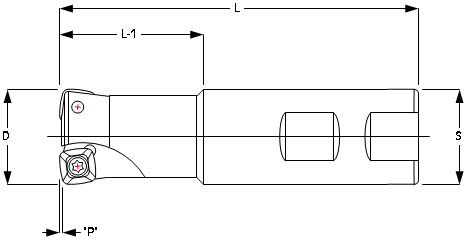

Shell Mount

- - Free Cutting Larger Diameter Shell Mills

- - Excellent Choice for High Speed 40 Taper Machines

- - Helical Mill Large Diameter Holes Without Overloading Your Spindle

- - Higher Feed Rates

- - Faster Material Removal

- - Ramping & Plunging Capabilities

| Tool Info. Shell Mount |

||||||||||

| Tool # | Flutes | D | L | Bore | Key | Plunge “P” | Ramp | Insert | Screw | Wrench |

| HF-2000S | 5 | 2.000 | 1.625 | .750 | .312 | .031 | 3° | ARP-33 | 538T | T-10 |

| HF-2500S | 6 | 2.500 | 1.750 | 1.000 | .375 | .031 | 2° | |||

| HF-3000S | 7 | 3.000 | 1.750 | 1.000 | .375 | .031 | 1.5° | |||

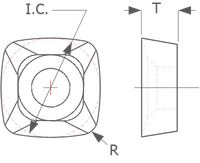

Insert Info.

| Insert Info. High Feed Mills |

||||

| Insert | I.C. | T | R | Grade |

| ARP-33 | .375 | .187 | .062 | C55 / K11 |

Technical Data

| Speed & Feed Info. High Feed Mills |

|||

| Material | S.F.M. | * Minimum

Depth of Cut .032 I.P.T. |

** Maximum Depth of Cut .089 I.P.T. |

| Mild & Low Carbon Steel EX.1018, 1020, 1117, 1141, 12L14 |

1000 - 1400 | .016 - .041 | .010 - .025 |

| High Carbon & Alloy Steel Ex. - 1045, 4140, 4340, 52100, 8620 |

800 - 1000 | .016 - .032 | .010 - .020 |

| Low Carbon Tool Steel Ex. - P-20, H-13, S-7 |

600 - 900 | .016 - .032 | .010 - .020 |

| Tool Steel Ex. - A-2, A-6, D-2, M-2 |

500 - 800 | .016 - .032 | .016 - .020 |

| Stainless Steel Ex. - 304, 316, 420, 15-5PH, 17-4PH |

500 - 800 | .016 - .032 | .016 - .020 |

| Iron Ex. Ductile |

800 - 1200 | .016 - .041 | .010 - .025 |

| Nickel & Titanium Alloy Ex. - Inconel, Hastelloy, TI-6A-4V |

350 - 450 | .008 - .024 | .005 - .015 |

| * Minimum depth of cut of .032" - Inserts have a 8X chip thinning factor. | |||

| ** Maximum depth of cut of .089" - Inserts have a 5X chip thinning factor. | |||

| Insert Grade Selection High Feed Mills |

||

| Material | Material Examples | Preferred Grade |

| Mild & Low Carbon Steels | 1018, 1020, 1117, 1141, 12L14 | K11 |

| High Carbon & Alloy Steels | 1045, 4140, 4340, 52100, 8620 | K11 |

| Lower Carbon Tool Steels | P-20, H-13, S-7 | K11 |

| Tool Steels | A-2, A-6, D-2, M-2 | K11 |

| Stainless Steels | 303, 304, 316, 420, 15-5PH, 17-4PH | K11 |

| Iron | Cast, Nodular | C55 / K11 |

| Iron | Ductile | K11 |

| Nickel & Titanium Alloys | Inconel, Hastelloy, TI-6AL-4V | K11 |

| Non-Ferrous Metals | Aluminum, Bronze, Brass | K11 |

| Insert Grade Description High Feed Mills |

||

| Grade | Description | |

| C55 | Multi-Layer Dense Coating | |

| K11 | Universal High Performance Dense Coating | |