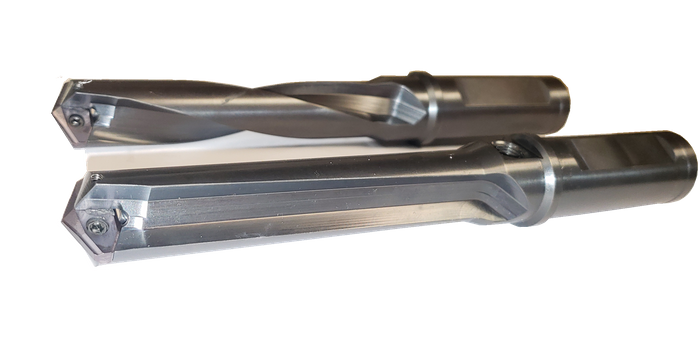

1.011 - 1.260 Diameter Drill Sergeants

- - Available in 2:1, 4:1 & 6:1 Ratio

- - Helical or Straight Flute Design

- - Coolant thru is standard

Patent # 5,259,707

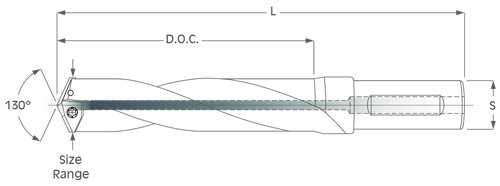

| Tool Info. | ||||||

| Helical Flute | 1.011 - 1.260 Dia. Drill Sergeants | |||||

| Tool # | Size Range | Standard Inserts | L | D.O.C. | Coolant Plug | S |

| DS-101-113S | 1.011 - 1.135 | DI-1031 / DI-1062 / DI-1093 / DI-1125 | 6.500 | 2.500 | NPT 1/4 | 1.000 |

| DS-101-113L | 9.000 | 5.000 | N/A | |||

| DS-101-113XL | 11.500 | 7.500 | N/A | |||

| DS-113-126S | 1.136 - 1.260 | DI-1156 / DI-1187 / DI-1218 / DI-1250 | 6.500 | 2.500 | NPT 1/4 | |

| DS-113-126L | 9.000 | 5.000 | N/A | |||

| DS-113-126XL | 11.500 | 7.500 | N/A | |||

| Standard Tap Sizes Highlighted in Red | ||||||

| Tool Info. | ||||||

| Straight Flute | 1.011 - 1.260 Dia. Drill Sergeants | |||||

| Tool # | Size Range | Standard Inserts | L | D.O.C. | Coolant Plug | S |

| DSL-101-113L | 1.011 - 1.135 | DI-1031 / DI-1062 / DI-1093 / DI-1125 | 9.000 | 5.000 | NPT 1/4 | 1.000 |

| DSL-101-113XL | 11.500 | 7.500 | ||||

| DSL-113-126L | 1.136 - 1.260 | DI-1156 / DI-1187 / DI-1218 / DI-1250 | 9.000 | 5.000 | ||

| DSL-113-126XL | 11.500 | 7.500 | ||||

| Use Straight Flute For Lathe and High Pressure Coolant Applications over 500 P.S.I. | ||||||

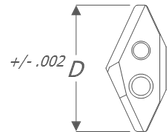

Insert Info.

| Insert Info. 1.011 - 1.260 Dia. Drill Sergeants |

||||

| Dia. Tolerance +/-.002 | ||||

| Insert # | D | Grade | Screw | Wrench |

| DI-1031 | 1.0312 | K11 | 638T | T-15 |

| DI-1062 | 1.0625 | X33 | ||

| DI-1093 | 1.0938 | |||

| DI-1125 | 1.1250 | |||

| DI-1156 | 1.1562 | |||

| DI-1187 | 1.1875 | |||

| DI-1218 | 1.2188 | |||

| DI-1250 | 1.2500 | K11 | ||

Technical Info.

Insert Loading Procedure

- - Air blast pocket clean

- - Hold insert in place

- - Tighten screws until each one makes light contact

- - Alternate tightening screws several times until screws are tight

| Speed and Feed Info. 1.011 - 1.260 Dia. Drill Sergeants |

||

| Material | S.F.M. | I.P.R. |

| Mild & Low Carbon Steel Ex. 1018, 1020, 1117, 1141, 12L14 |

700 - 900 | .006 - .010 |

| High

Carbon & Alloy Steel Ex. 1045, 4140, 4340, 52100, 8620 |

500 - 600 | .006 - .010 |

| Lower

Carbon Tool Steel Ex. P-20, H-13, S-7 |

400 - 500 | .006 - .010 |

| Tool

Steel Ex. A-2, A-6, D-2, M-2 |

350 - 450 | .006 - .010 |

| Stainless

Steel Ex. 304, 316, 420, 15-5PH, 17-4PH |

350 - 550 | .005 - .008 |

| Iron Ex. Cast, Ductile, Nodular |

600 - 800 | .008 - .014 |

| Nickel

& Titanium Alloy Ex. Inconel, Hastelloy, TI-6AL-4V |

100 - 200 | .003 - .005 |

| Non-Ferrous

Ex. Aluminum, Bronze, Brass |

1000 - 2000 | .008 - .014 |

| Insert Grade Selection | ||

| Material | Material Examples | Preferred Grade |

| High & Low Carbon Steels | 1018, 1020, 1117, 1141, 12L14 | K11 or X33 |

| High Carbon & Alloy Steels | 1045, 4140, 4340, 52100, 8620 | K11 or X33 |

| Lower Carbon Tool Steels | P-20, H-13, S-7 | K11 or X33 |

| Tool Steels | A-2, A-6, D-2, M-2 | K11 or X33 |

| Stainless Steels | 303, 304, 316, 420, 15-5PH, 17-4PH | K11 or X33 |

| Iron | Cast, Nodular | K11 or X33 |

| Iron | Ductile | K11 or X33 |

| Nickel & Titanium Alloys | Inconel, Hastelloy, TI-6AL-4V | K11 or X33 |

| Non-Ferrous Metals | Aluminum, Bronze, Brass | K11 or X33 |

| Insert Grade Description | |

| Grade | Description |

| X33 | High Performance Nitride |

| K11 | Universal High Performance Dense Coating |

| **X33 will be replaced with K11 as inventory runs out ** |

|