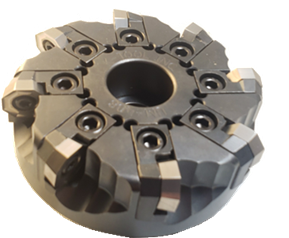

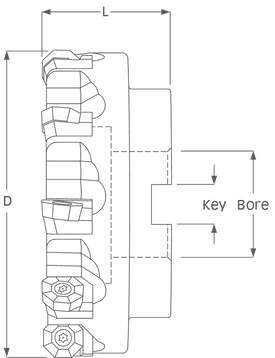

4.000 - 10.000 Diameter Universal Mills

Multi-Geometry Cartridge Style Face Mills

- Illustration Shown with Octa - Cartridges.

- Choose from any of the cartridges listed below.

| Tool Info. Universal Mills |

||||||||

| Tool # | D | Flutes | L | Bore | Key | Cartridge Screw |

Allen Wrench |

Adjustment Screw |

| UM-408 | 4.000 | 8 | 1.875 | 1.250 | .500 | 142878 | 3/16" | 1/4-28 x 3/8” |

| UM-510 | 5.000 | 10 | 2.000 | 1.500 | .625 | |||

| UM-612 | 6.000 | 12 | 2.000 | 1.500 | .625 | |||

| UM-816 | 8.000 | 16 | 2.250 | 2.500 With 4 Bolt Hole Pattern |

1.000 | |||

| UM-1020 | 10.000 | 20 | 2.250 | 1.000 | ||||

30 Degree Cartridge

- Insert: SPEB-43-30PA

- Insert Screw: 638T

- Wrench: T-15

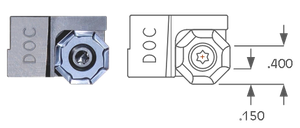

DOC Cartridge

- Insert: ONPG-4532

- Insert Screw: 838T

- Wrench: T-20

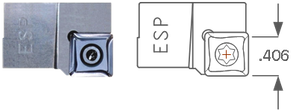

ESP Cartridge

- Insert: SNPG-3532

- Insert Screw: 538T

- Wrench: T-10

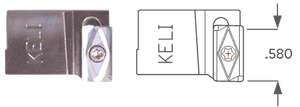

Keli Cartridge

- Insert: LPMT-52-532 / 533 / 534

- Insert Screw: 560T

- Wrench: T-10

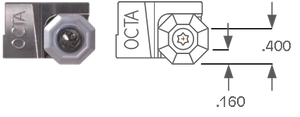

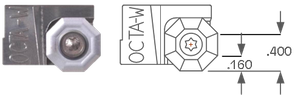

OCTA Wiper Cartridge

- Insert: OPEB-535

- Insert Screw: 838T

- Wrench: T-20

Radius Cartridge

- Insert: MGH-530 SERIES

- Insert Screw: 560T

- Wrench: T-10

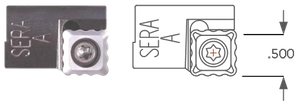

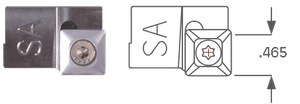

SA Cartridge

- Insert: SNEB-432PA

- Insert Screw: 638T

- Wrench: T-15

- Standard Insert Information - The standard insert page contains detailed

- information for all of the inserts listed above

Technical Data

| Speed and Feed Info. Universal Mill |

||

| Material | S.F.M. | I.P.T. |

| Mild & Low Carbon Steel Ex. 1018, 1020, 1117, 1141, 12L14 |

800 - 1200 | .002 - .006 |

| High

Carbon & Alloy Steel Ex. 1045, 4140, 4340, 52100, 8620 |

500 - 800 | .002 - .005 |

| Lower

Carbon Tool Steel Ex. P-20, H-13, S-7 |

400 - 700 | .002 - .005 |

| Tool

Steel Ex. A-2, A-6, D-2, M-2 |

300 - 600 | .002 - .004 |

| Stainless

Steel Ex. 304, 316, 420, 15-5PH, 17-4PH |

300 - 600 | .002 - .004 |

| Iron Ex. Cast, Ductile, Nodular |

600 - 1000 | .003 - .007 |

| Nickel

& Titanium Alloy Ex. Inconel, Hastelloy, TI-6AL-4V |

120 - 180 | .001 - .003 |

| Non-Ferrous

Metal Ex. Aluminum, Bronze, Brass |

1000 - 2500 | .003 - .007 |

| Insert Grade Selection | ||

| Material | Material Examples | Preferred Grade |

| Mild & Low Carbon Steels | 1018, 1020, 1117, 1141, 12L14 | X33 |

| High Carbon & Alloy Steels | 1045, 4140, 4340, 52100, 8620 | X33 |

| Lower Carbon Tool Steels | P-20, H-13, S-7 | X33 |

| Tool Steels | A-2, A-6, D-2, M-2 | X33 |

| Stainless Steels | 303, 304, 316, 420, 15-5PH, 17-4PH | X33 |

| Iron | Cast, Nodular | C55 , X33 |

| Iron | Ductile | X33 |

| Nickel & Titanium Alloys | Inconel, Hastelloy, TI-6AL-4V | X33 |

| Non-Ferrous Metals | Aluminum, Bronze, Brass | X40 / B1M / X33 |

| Insert Grade Description | |

| Grade | Description |

| B1M | Uncoated Carbide - No Hone |

| C55 | Multi-Layer Power Nitride Coating |

| X33 | High Performance Nitride Coating |

| X40 | Extremely Smooth Boride Coating |