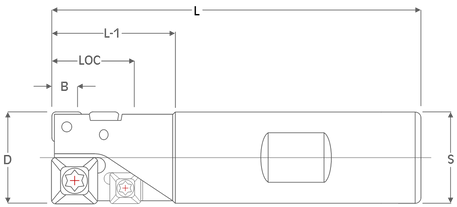

.750 & 1.000 Diameter Drill Mill Twin Long Edge

2 Effective Center Cutting Long Edge End Mills

- - 2 Flutes Effective when Milling or Counterboring

- - Center cutting

- - Cuts a flat bottom within .001

| Tool Info. .750 & 1.000 Dia. |

||||||||||||

| Tool # | D | L | L-1 | B | LOC | S | Insert | Screw | Wrench | Center Insert | Screw | Wrench |

| DMTL-750 | .750 | 3.000 | 1.000 | .215 | .700 | .750 | (3) SPEB-222P | 314T | T-8 | (1) SPEB-322P | 414T | T-10 |

| DMTL-100 | 1.000 | 3.750 | 1.500 | .280 | .900 | 1.000 | (3) SPEB-2522P | 314T | T-8 | (1) SPEB-422PA | 638T | T-15 |

Note: DMTL's are to be run as 1 flute effective at depths more than "B" dimension

DMTL's will let witness lines

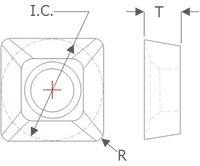

Insert Info.

| Insert Info. .750 Dia. Drill Mill Twin Long Edge |

||||

| Insert # | I.C. | T | R | Grades |

| SPEB-222P | .250 | .125 | .031 | B1M / D66 / K11 / X40 |

| SPEB-322P | .375 | .125 | .031 | B1M / D66 / K11 / X40 |

| Insert Info. 1.000 Dia. Drill Mill Twin Long Edge |

||||

| Insert # | I.C. | T | R | Grades |

| SPEB-2522P | .312 | .125 | .031 | K11 |

| SPEB-422PA | .500 | .125 | .031 | X33 |

Technical Data

| Speed and Feed Info. Drill Mill Twin Long Edge |

|||

| Material | S.F.M. | Drilling I.P.R. |

Milling I.P.R. |

| Mild

& Low Carbon Steel Ex. 1018, 1020, 1117, 1141, 12L14 |

400 - 800 | .002 - .004 | .002 - .005 |

| High

Carbon & Alloy Steel Ex. 1045, 4140, 4340, 52100, 8620 |

300 - 500 | .002 - .003 | .002 - .004 |

| Lower

Carbon Tool Steel Ex. P-20, H-13, S-7 |

300 - 500 | .002 - .003 | .002 - .004 |

| Tool

Steel Ex. A-2, A-6, D-2, M-2 |

300 - 500 | .001 - .003 | .001 - .004 |

| Stainless

Steel Ex. 304, 316, 420, 15-5PH, 17-4PH |

300 - 500 | .001 - .003 | .001 - .003 |

| Iron Ex. Cast, Ductile, Nodular |

400 - 800 | .002 - .005 | .002 - .006 |

| Nickel

& Titanium Alloy Ex. Inconel, Hastelloy, TI-6AL-4V |

100 - 200 | .001 - .002 | .001 - .002 |

| Non-Ferrous

Metal Ex. Aluminum, Bronze, Brass |

800 - 1200 | .003 - .006 | .003 - .008 |

| Insert Grade Selection .750 & 1.000 Dia. Drill Mill Twin Long Edge |

||

| Material | Material Examples | Preferred Grade |

| Mild & Low Carbon Steels | 1018, 1020, 1117, 1141, 12L14 | K11 or X33 |

| High Carbon & Alloy Steels | 1045, 4140, 4340, 52100, 8620 | K11 or X33 |

| Lower Carbon Tool Steels | P-20, H-13, S-7 | K11 or X33 |

| Tool Steels | A-2, A-6, D-2, M-2 | K11 or X33 |

| Stainless Steels | 303, 304, 316, 420, 15-5PH, 17-4PH | K11 or X33 |

| Iron | Cast, Nodular | D66 / K11 or X33 |

| Iron | Ductile | K11 or X33 |

| Nickel & Titanium Alloys | Inconel, Hastelloy, TI-6AL-4V | K11 or X33 |

| Non-Ferrous Metals | Aluminum, Bronze, Brass | B1M / X40 / K11 or X33 |

| Insert Grade Description .750 & 1.000 Dia. Drill Mill Twin Long Edge |

|

| Grade | Description |

| B1M | Uncoated Carbide - No Hone |

| D66 | Multi-Layer Dense Coating |

| K11 | Universal High Performance Dense Coating |

| X33 | High Performance Nitride |

| X40 | Extremely Smooth Boride Coating / Periphery Ground |

| **X33 will be replaced with K11 as inventory runs out ** |

|