Serators - Shank Tools

Long Edge Roughing Mills .615 - 1.980 Dia.

- - .010 - .020 undersize for finishing

- - Serrated insert edge reduces tool pressure

IMPORTANT

- High Pressure Flood Coolant or Air Blast Required to Disperse Chip and cool the tool.

- Recutting chips will cause early insert failure

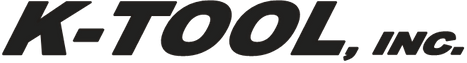

| Tool Info. Serators - Shank Tools |

||||||||||

| Tool # | D | Flutes | Inserts | L | L-1 | L.O.C. | S | Inserts | Screw | Wrench |

| S-625 | .615 | 2-1 Effective | 6 | 3.000 | .900 | .750 | .625 | SNMC-222B SNMC-221P |

314T | T-8 |

| S-750 | .740 | 2-1 Effective | 8 | 3.375 | 1.125 | 1.000 | .750 | |||

| S-100S | .985 | 2-1 Effective | 4 | 3.125 | 1.125 | .780 | .750 | SNMC-333B SNGC-333H SNMC-332P |

538T | T-10 |

| S-100M | .985 | 2-1 Effective | 6 | 3.625 | 1.375 | 1.125 | 1.000 | |||

| S-100 | .985 | 2-1 Effective | 8 | 4.000 | 1.750 | 1.500 | 1.000 | |||

| S-125S | 1.235 | 3-1.5 Effective | 9 | 3.750 | 1.500 | 1.125 | 1.000 | |||

| S-125 | 1.235 | 3-1.5 Effective | 15 | 4.625 | 2.375 | 1.900 | 1.250 | |||

| S-125L | 1.235 | 2-1 Effective | 16 | 5.625 | 3.375 | 3.062 | 1.250 | |||

| S-150S | 1.485 | 3-1.5 Effective | 9 | 3.875 | 1.625 | 1.125 | 1.000 | |||

| S-150 | 1.485 | 3-1.5 Effective | 18 | 4.875 | 2.500 | 2.250 | 1.250 | |||

| S-150L | 1.485 | 3-1.5 Effective | 33 | 7.250 | 4.625 | 4.200 | 1.500 | |||

| S-200 | 1.980 | 4-2 Effective | 20 | 5.750 | 3.125 | 2.550 | 1.500 | SNMC-444B SNMC-443P |

838T | T-20 |

Insert Info.

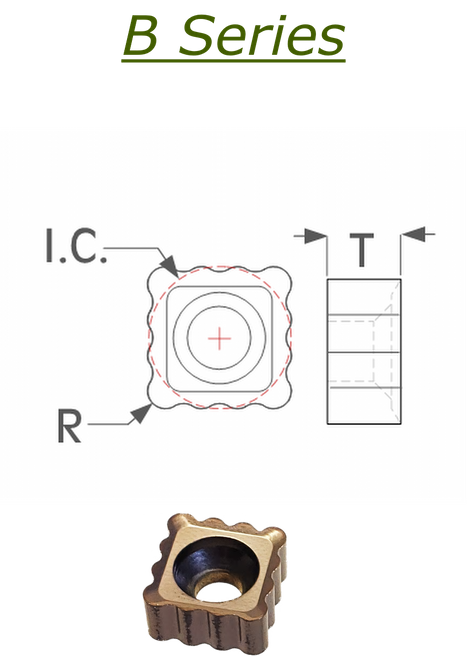

- SNMC - B: General purpose roughing insert with serrations molded on the side of the insert.

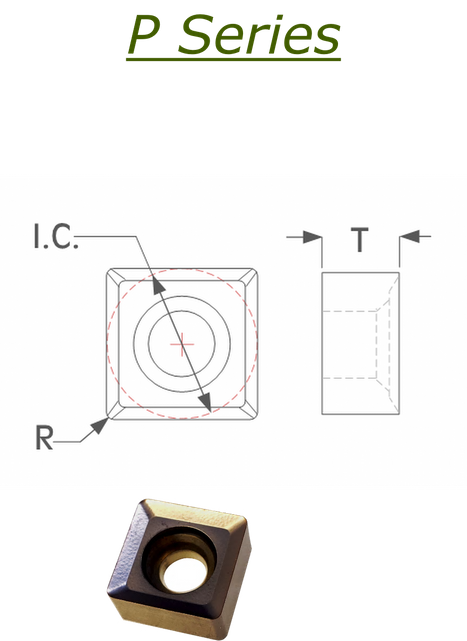

- SNMC - P: Molded positive top Semi- Finishing insert with no serrations.

- SNGC - H: Roughing inserts with serrations molded on the top and periphery ground for Titanium, Stainless & Nickel

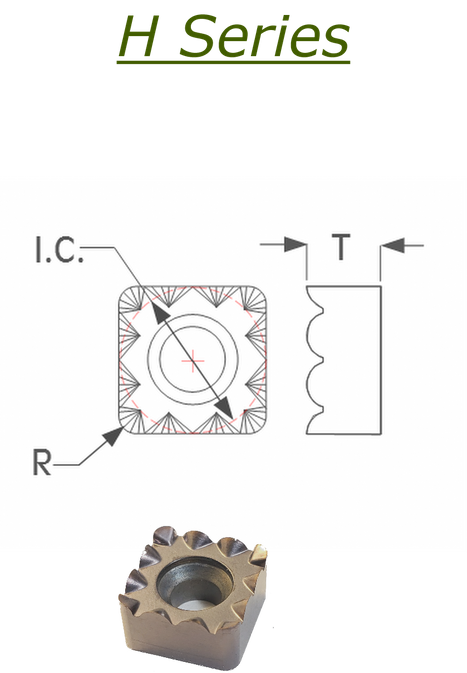

| SNMC - B Inserts | SNMC - P Inserts | SNGC - H Inserts | ||||||||||||||

| Insert # | I.C. | T | R | Grade | Insert # | I.C. | T | R | Grades | Insert # | I.C. | T | R | Grade | ||

| SNMC-222B | .250 | .125 | .031 | K11 | SNMC-221P | .250 | .125 | .015 | X33 | SNGC-333H | .375 | .187 | .047 | K11 | ||

| SNMC-333B | .375 | .187 | .047 | K11 | SNMC-332P | .375 | .187 | .031 | K11 | |||||||

| SNMC-444B | .500 | .250 | .062 | K11 | SNMC-443P | .500 | .250 | .047 | C55 / K11 | |||||||

Technical Info.

| Speed and Feed Info. .615 & .740 Dia. Serators |

||

| Material | S.F.M. | I.P.T. |

| Mild & Low Carbon Steel Ex. 1018, 1020, 1117, 1141, 12L14 |

600 - 1200 | .002 - .003 |

| High

Carbon & Alloy Steel Ex. 1045, 4140, 4340, 52100, 8620 |

500 - 800 | .002 - .003 |

| Lower

Carbon Tool Steel Ex. P-20, H-13, S-7 |

400 - 700 | .002 - .003 |

| Tool

Steel Ex. A-2, A-6, D-2, M-2 |

300 - 600 | .002 - .003 |

| Stainless

Steel Ex. 304, 316, 420, 15-5PH, 17-4PH |

300 - 600 | .002 - .003 |

| Iron Ex. Cast, Ductile, Nodular |

600 - 1000 | .003 - .004 |

| Nickel

& Titanium Alloy Ex. Inconel, Hastelloy, TI-6AL-4V |

100 - 180 | .001 - .002 |

| Speed and Feed Info. .985 - 1.980 Dia. Serators |

||

| Material | S.F.M. | I.P.T. |

| Mild & Low Carbon Steel Ex. 1018, 1020, 1117, 1141, 12L14 |

600 - 1200 | .002 - .006 |

| High

Carbon & Alloy Steel Ex. 1045, 4140, 4340, 52100, 8620 |

500 - 800 | .002 - .004 |

| Lower

Carbon Tool Steel Ex. P-20, H-13, S-7 |

400 - 700 | .002 - .004 |

| Tool

Steel Ex. A-2, A-6, D-2, M-2 |

300 - 600 | .002 - .004 |

| Stainless

Steel Ex. 304, 316, 420, 15-5PH, 17-4PH |

300 - 600 | .002 - .004 |

| Iron Ex. Cast, Ductile, Nodular |

600 - 1000 | .003 - .006 |

| Nickel

& Titanium Alloy Ex. Inconel, Hastelloy, TI-6AL-4V |

100 - 180 | .001 - .003 |

| Insert Grade Selection | ||

| Material | Material Examples | Preferred Grade |

| Mild & Low Carbon Steels | 1018, 1020, 1117, 1141, 12L14 | K11 or X33 |

| High Carbon & Alloy Steels | 1045, 4140, 4340, 52100, 8620 | K11 or X33 |

| Lower Carbon Tool Steels | P-20, H-13, S-7 | K11 or X33 |

| Tool Steels | A-2, A-6, D-2, M-2 | K11 or X33 |

| Stainless Steels | 303, 304, 316, 420, 15-5PH, 17-4PH | K11 or X33 |

| Iron | Cast, Nodular | C55 / K11 or X33 |

| Iron | Ductile | K11 or X33 |

| Nickel & Titanium Alloys | Inconel, Hastelloy, TI-6AL-4V | K11 or X33 |

| Insert Grade Description | ||

| Grade | Description | |

| K11 | Universal High Performance Dense Coating | |

| X33 | High Performance Nitride | |

| C55 | Advanced Multi-Layer PVD Coated Carbide | |